今日要闻

推荐展会

更多 > >

橡胶挤出机螺杆构型及自动化生成系统

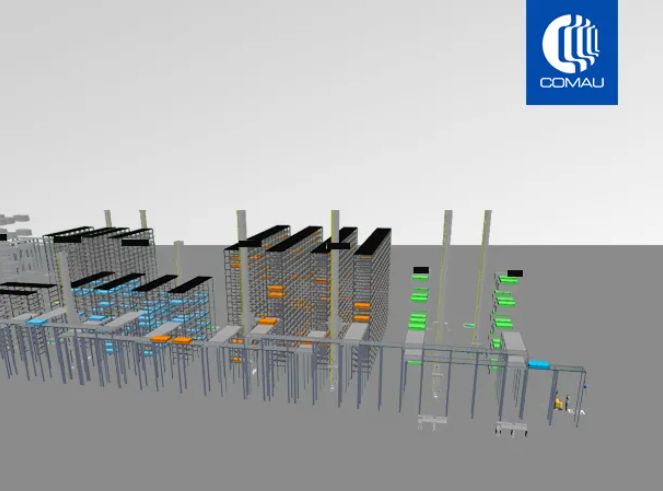

在橡胶工业中,螺杆挤出机是非常重要的加工设备。螺杆挤出机是随着其核心部件——挤出螺杆构型的发展而发展的,因此螺杆构型的研究是螺杆挤出机研究的热点之一。本论文在分析各种螺杆结构特点的基础上,对螺杆构型进行了理论分析 。分析了各种螺杆构型的挤出机理、主要作用及其优缺点;分析了各种螺杆构型对挤出过程的影响。研究不同构型螺杆的工作原理及对挤出过程的影响,必将有利于螺杆结构设计的进一步优化,和新型螺杆的开发,从而有利于橡胶工业的发展;而且对不同构型螺杆结构特点的研究是橡胶螺杆CAD系统开发的基础。也是优化橡胶螺杆CAD系统设计功能的基础。目前橡胶机械CAD 多采用在AutoCAD或者PRO-E上进行一些简单的二次开发,这种开发是建立在结构化基础上的,不但重用性非常差无法进行深层次开发,而且还难以满足复杂系统多元化的需求,难以实现扩展和重用,也难以解决橡胶机械CAD系统设计中跨进程、跨平台移植和分布式应用等方面的问题。要解决这些问题,系统设计模式的选取和系统的可重用和可扩展性便成为系统设计的关键所在。而目前可利用多种设计模式来巧妙地复用软件对象,从顶层的角度设计软件的系统结构;基于COM的组件对象模型*可以实现基于二进制可执行代码级的多种形式的兼容,从而很好地实现重用。基于COM的组件对象模型是实现橡胶CAD系统的一条“可行之路”。本论文在对不同螺杆构型研究的基础上,根据橡胶挤出机螺杆CAD参数化设计的特点,采用C++面向对象的开发语言,并采用COM组件作为功能单元进行了橡胶挤出机螺杆自动化生成系统结构设计,系统可以方便的实现将来的扩展和代码重用并用于实现分布式应用,这大大地提高了开发效率。zui后在Visual C++ 6.0开发平台上,在“可行之路”思想的指导下,完成了基于COM的“橡胶螺杆自动化生成系统”的开发。

The screw extruder plays an important role in rubber industry .The rubber screw extruder develops with the development of the screw configuration . Therefore the research on the screw configurtion is one of hot issues . Many screw configurations were analysized in this paper. The research mainly focused on how the screw configuration functions in the extruding process ; How the screw configuration impacts the extruding process was also analysized in the paper.The reseach on the screw configuration will advance and optimize screw design and it will also contribute to the developing of new type of screws. The reseach on the screw configuration is the base of developing and a CAD system for screw design . It is also the base of optimizing the function of a CAD system for screw design .Presently, the re-development of a CAD system for screw design by AutoCAD or PRO-E is mainly based on the structural program. It cann’t meet diverse requirements of complex systems such as application among different processes, platforms, distributed application and reuse. To solve these problems, it is critical to select the designing pattern of a CAD system and to think about reuse capacity and extended capacity. The Component Object Models (COM) is a feasible plan that developed a CAD system for screw design. According to the characteristic of parameterized screw design, the structure of the CAD system for screw design was designed in the paper. It used Component Object Models (COM) as a unit. This method can greatly improve the efficency of development. The C++ was used as programming language and Visual C++ 6.0 was used as the platform of development for developing the CAD system for screw design. At last, the CAD system for screw design was developed on the basis of the above motheds .The CAD system for screw design was flexible for its extension and code’s reuse .It can also be used for distributed application.

The screw extruder plays an important role in rubber industry .The rubber screw extruder develops with the development of the screw configuration . Therefore the research on the screw configurtion is one of hot issues . Many screw configurations were analysized in this paper. The research mainly focused on how the screw configuration functions in the extruding process ; How the screw configuration impacts the extruding process was also analysized in the paper.The reseach on the screw configuration will advance and optimize screw design and it will also contribute to the developing of new type of screws. The reseach on the screw configuration is the base of developing and a CAD system for screw design . It is also the base of optimizing the function of a CAD system for screw design .Presently, the re-development of a CAD system for screw design by AutoCAD or PRO-E is mainly based on the structural program. It cann’t meet diverse requirements of complex systems such as application among different processes, platforms, distributed application and reuse. To solve these problems, it is critical to select the designing pattern of a CAD system and to think about reuse capacity and extended capacity. The Component Object Models (COM) is a feasible plan that developed a CAD system for screw design. According to the characteristic of parameterized screw design, the structure of the CAD system for screw design was designed in the paper. It used Component Object Models (COM) as a unit. This method can greatly improve the efficency of development. The C++ was used as programming language and Visual C++ 6.0 was used as the platform of development for developing the CAD system for screw design. At last, the CAD system for screw design was developed on the basis of the above motheds .The CAD system for screw design was flexible for its extension and code’s reuse .It can also be used for distributed application.

- 凡本网注明"来源:塑料机械网"的所有作品,版权均属于塑料机械网,转载请必须注明塑料机械网,https://www.86pla.com。违反者本网将追究相关法律责任。

- 企业发布的公司新闻、技术文章、资料下载等内容,如涉及侵权、违规遭投诉的,一律由发布企业自行承担责任,本网有权删除内容并追溯责任。

- 本网转载并注明自其它来源的作品,目的在于传递更多信息,并不代表本网赞同其观点或证实其内容的真实性,不承担此类作品侵权行为的直接责任及连带责任。其他媒体、网站或个人从本网转载时,必须保留本网注明的作品来源,并自负版权等法律责任。

- 如涉及作品内容、版权等问题,请在作品发表之日起一周内与本网联系,否则视为放弃相关权利。