全自动复合保温轻质墙板生产线Automatic Composite light panel production line

生产流水线工艺设备Production line equipment:

(1)蒸汽锅炉 (2)蒸汽储气罐 (3)EPS发泡机 (4)硫化干燥床

(5)EPS颗粒储料熟化仓 (6)EPS颗粒计量仓 (7)散装料提升机 (8)搅拌机

(9)水计量称 (10)粉状料电子计量称 (11)自动控制中心 (12)螺旋输送机

(13)粉状料储料罐 (14)成型模具车 (15)横向自动摆渡车 (16)纵向自动牵引装置(17)吊运小车 (18)运输叉车 (19)成品板材

流水线生产工艺:配料→搅拌→挤出成型→固化→脱模→切割→养护→检验出厂。

Production process: batching → stirring → extrusion molding → curing → stripping → cutting →maintain→ Factory inspection.

主要特点/ Main features of our products:

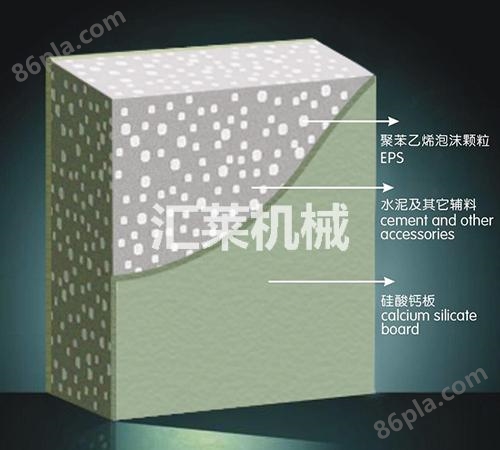

全自动复合轻质墙板生产线是我公司根据国家相关要求,面向市场,生产硅酸钙板聚苯颗粒水泥复合夹芯隔墙板的自动化设备。

Ø 该设备上料系统计量准确,采用自动模具车、自动拖板机,自动化程度高;

Ø 搅拌系统搅拌均匀、结构紧凑、外形美观、运转平稳、操作方便、生产效率高;

Ø 浇筑模具精度准确,严密性好,安装方便,所产板材外形稳定,不变形,不开裂;

Ø 主要工艺设备:蒸汽锅炉、EPS发泡机、全自动搅拌站、全自动成型模具车、自动卸板机、自动循环系统。

Ø Automatic composite light wallboard production line is an automatic equipment for producing composite sandwich wallboard combined calcium silicate board with polystyrene foam particle cement.

Ø The feeding system of the equipment adopts automatic mold car and automatic plate-dragging machine, that is accurate in measurement with high degree of automation;

Ø The mixing system has the advantages of mixing uniformly, compact structure, beautiful appearance, smooth operation, easy operation and high production efficiency;

Ø The casting mould has the advantages of accurate precision, good tightness and easy installation.

Ø Main equipment: steam boiler, EPS foaming machine, automatic mixing plant, automatic mold car, automatic plate unloading machine, automatic circulation system.