不锈钢截止阀产品概述

不锈钢截止阀与流体介质接触的零部件均采用不锈钢材料生产制造的截止阀就是不锈钢截止阀,功能特征和普通截止阀一样,虽然不锈钢截止阀价格昂贵,但是由于是不锈钢材质作为主要的结构件,不仅可以用于水、油、气介质,还可以用于各种腐蚀性介质。不锈钢截止阀厂家通常采用CF8和CF8M奥氏体不锈钢制造,不仅可以在常温环境中使用,还可以用于高于400°的高温环境和低于-29度的低温环境。 不锈钢呈金属光泽,不需要油漆涂装,不锈钢在腐蚀性介质会自动形成钝化膜,防止介质腐蚀阀门,在高温腐蚀性截止阀中有不可替代的地位,即使用于普通其寿命也远优于普通铸钢截止阀,大大提高生产效率。铸钢截止阀产品执行标准

| 产品规范 Product specification | 设计与制造 Design manufacture | 结构长度 Structure length | 压力-温度 Pressure temperature | 法兰尺寸 Flange size | 检验与实验 Inspection experiment |

| GB/T 12235 | GB/T 12221 | GB/T 9131 | JB/T 79 GB/T 9113 HG 20592 | GB/T 13927 JB/T 9094 |

铸钢截止阀产品特征

| J41H/Y 型 PN16~PN160 钢制截止阀主要性能参数 | ||||

| 型号 | PN | 工作压力 / MPa | 适用温度 / ℃ | 适用介质 |

| J41H/Y -16C~160C | 16~160 | 1.6~16.0 | ≤425 | 水、蒸汽、油品 |

| J41H/Y-16P~160P | ≤150 | 弱腐蚀性介质 | ||

| J41H/Y-16R~160R | 腐蚀性介质 | |||

| J41H/Y-16I~160I | ≤550 | 油品、蒸汽 | ||

铸钢截止阀产品零部件材料

| 序号 NO. | 零件名称 Parts name | 材料 Material | ||||

| WCB | WC6 | WC9 | CF8 | CF8M | ||

| 1 | 阀体 Body | WCB | WC6 | WC9 | CF8 | CF8M |

| 2 | 阀瓣 Disc | 2Cr13 | 25Cr2MoV | 25Cr2MoV | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 3 | 阀杆 Stem | 2Cr13 | 25Cr2MoV | 25Cr2MoV | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 4 | 阀瓣盖 Disc cover | 2Cr13 | 25Cr2MoV | 25Cr2MoV | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 5 | 垫片 Gasket | 柔性石墨 Flexible graphite | ||||

| 6 | 阀盖 Bonnet | WCB | WC6 | WC9 | CF8 | CF8M |

| 7 | 螺柱 Stud | 35CrMo | 35CrMo | 35CrMo | 1Cr18Ni9 | 1Cr18Ni9 |

| 8 | 螺母 Nut | 35CrMo | 35CrMo | 35CrMo | 1Cr18Ni9 | 1Cr18Ni9 |

| 9 | 填料 Filler | 柔性石墨 Flexible graphite | ||||

| 10 | 压板 Press plate | WCB | WC6 | WC9 | CF8 | CF8M |

| 11 | 阀杆螺母 Stem nut | 铜合金 Copper alloy | ||||

| 12 | 手轮 Hand wheel | 球墨铸铁 Ductile iron | ||||

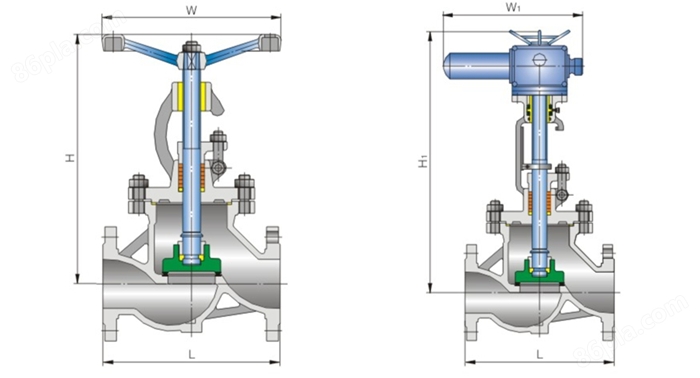

铸钢截止阀产品结构尺寸

| 压力级 MPa | 公称通径 DN | 尺寸 Dimension | ||||||

| L | D | D1 | D2 | b | f | Z-d | ||

| J41H J541H J941H 1.6MPa | 15 | 130 | 95 | 65 | 45 | 14 | 2 | 4-14 |

| 20 | 150 | 105 | 75 | 55 | 16 | 2 | 4-14 | |

| 25 | 160 | 115 | 85 | 65 | 16 | 2 | 4-14 | |

| 32 | 180 | 135 | 100 | 78 | 18 | 2 | 4-18 | |

| 40 | 200 | 145 | 110 | 85 | 18 | 2 | 4-18 | |

| 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-18 | |

| 65 | 290 | 180 | 145 | 120 | 20 | 3 | 4-18 | |

| 80 | 310 | 195 | 160 | 135 | 20 | 3 | 8-18 | |

| 100 | 350 | 215 | 180 | 155 | 22 | 3 | 8-18 | |

| 125 | 400 | 245 | 210 | 185 | 22 | 3 | 8-18 | |

| 150 | 480 | 280 | 240 | 210 | 24 | 3 | 8-23 | |

| 200 | 600 | 335 | 295 | 265 | 26 | 3 | 12-23 | |

| 250 | 650 | 405 | 355 | 320 | 28 | 3 | 12-25 | |

| 300 | 750 | 460 | 410 | 375 | 30 | 4 | 12-25 | |

| J41H J541H J941H 2.5MPa | 15 | 130 | 95 | 65 | 45 | 14 | 2 | 4-14 |

| 20 | 150 | 105 | 75 | 55 | 16 | 2 | 4-14 | |

| 25 | 160 | 115 | 85 | 65 | 16 | 2 | 4-14 | |

| 32 | 180 | 135 | 100 | 78 | 18 | 2 | 4-18 | |

| 40 | 200 | 145 | 110 | 85 | 18 | 2 | 4-18 | |

| 50 | 230 | 160 | 125 | 100 | 22 | 3 | 4-18 | |

| 65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-18 | |

| 80 | 310 | 195 | 160 | 135 | 24 | 3 | 8-18 | |

| 100 | 350 | 230 | 190 | 160 | 26 | 3 | 8-23 | |

| 125 | 400 | 270 | 220 | 188 | 26 | 3 | 8-25 | |

| 150 | 480 | 300 | 250 | 218 | 28 | 3 | 8-25 | |

| 200 | 600 | 360 | 310 | 278 | 30 | 3 | 12-25 | |

| 250 | 650 | 425 | 370 | 332 | 32 | 3 | 12-30 | |

| 300 | 750 | 485 | 430 | 390 | 34 | 4 | 16-30 | |

| J41H J541H J941H 4.0MPa | 15 | 130 | 95 | 65 | 45 | 14 | 2 | 4-14 |

| 20 | 150 | 105 | 75 | 55 | 16 | 2 | 4-14 | |

| 25 | 160 | 115 | 85 | 65 | 16 | 2 | 4-14 | |

| 32 | 180 | 135 | 100 | 78 | 18 | 2 | 4-18 | |

| 40 | 200 | 145 | 110 | 85 | 18 | 2 | 4-18 | |

| 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-18 | |

| 65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-18 | |

| 80 | 310 | 195 | 160 | 135 | 24 | 3 | 8-18 | |

| 100 | 350 | 230 | 190 | 160 | 24 | 3 | 8-23 | |

| 125 | 400 | 270 | 220 | 188 | 26 | 3 | 8-25 | |

| 150 | 480 | 300 | 250 | 218 | 28 | 3 | 8-25 | |

| 200 | 600 | 375 | 320 | 282 | 34 | 3 | 12-30 | |

| J41H J541H J941H 6.4MPa | 15 | 170 | 105 | 75 | 55 | 18 | 2 | 4-14 |

| 20 | 190 | 125 | 90 | 68 | 20 | 2 | 4-14 | |

| 25 | 210 | 135 | 100 | 78 | 22 | 2 | 4-18 | |

| 32 | 230 | 150 | 110 | 82 | 24 | 2 | 4-18 | |

| 40 | 260 | 165 | 125 | 95 | 24 | 2 | 4-23 | |

| 50 | 300 | 175 | 135 | 105 | 26 | 3 | 4-23 | |

| 65 | 340 | 200 | 160 | 130 | 26 | 3 | 8-23 | |

| 80 | 380 | 210 | 170 | 140 | 28 | 3 | 8-23 | |

| 100 | 430 | 250 | 200 | 168 | 30 | 3 | 8-25 | |

| 125 | 500 | 295 | 240 | 202 | 34 | 3 | 8-30 | |

| 150 | 550 | 340 | 280 | 240 | 36 | 3 | 8-34 | |

| 200 | 650 | 405 | 345 | 300 | 42 | 3 | 12-34 | |