|

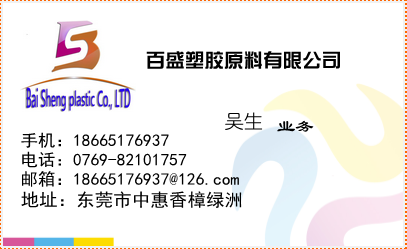

百事順塑胶原料有限公司

主营产品: 工程塑料 |

|

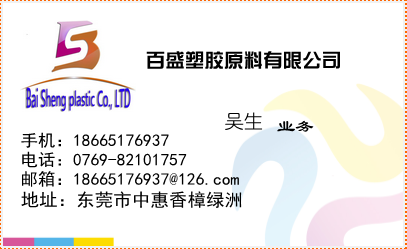

百事順塑胶原料有限公司

主营产品: 工程塑料 |

| 参考价 | 面议 |

塑料机械网采购部电话:0571-88918531 QQ:2568841715

QQ:2568841715

联系方式:查看联系方式

更新时间:2018-05-15 17:41:40浏览次数:227

联系我们时请说明是塑料机械网上看到的信息,谢谢!

我公司销售的材料均为*材料,咨询采购! 吴生 186 6517 6937

The essential ingredient for design, cushioning and durability

Lubrizol's product portfolio is preferred by end-users, design engineers and processors for its outstanding properties in demanding and high abuse applications. This is why footwear is an ideal application for our engineered polymers, such as thermoplastic polyurethane (TPU).

Outstanding benefits:

Application Possibilities:

Estane 特种聚合物 >高湿蒸汽透射(HMVT)

Estane 特种聚合物的湿蒸汽透射(HMVT)性能范围非常宽,可以满足服装领域和医疗伤口护理市场等严格的要求。 本技术之所以具有*性,是因为该材料在薄膜或涂层形态时,会形成一个防水,但却仍可让水蒸气通过活性扩散作用自由流动的屏障。

Estane的HMVT将薄膜的韧性、柔软性和弹性性能与阻透保护型相结合,同时通过提供湿气渗透作用提供舒适性。 其*的化学结构允许zui终用户在特定应用中控制他们所需要的透气性。 我们的特种聚合物具有不同的透气性,从350 g/m2/24hrs* MVT的适度透气,到760 g/m2/24hrs* HMVT的高透气性 。

Enhanced Isoplast thermoplastic polyurethane products also include?Long glass enhanced ETPU, this product has a very high ductility and bearing capacity at the same time.Such, the bending modulus of the solid polymer up to 2 million psi, can be widely replace metal and used as a structural component.Isoplast engineering thermoplastic urethane (ETPU) both amorphous resin toughness and shape stability, as well as the excellent properties of semi crystalline resin and chemical resistance.

Glass enhanced Isoplast low melt viscosity is one of the characteristics of products, so the less gate and lower clamp pressure can shape the larger parts.In addition, these materials are also very beautiful, glass grain is less, and excellent stability.With competitive polymers such as nylon, the shrinkage is very uniform, and low moisture absorption.

Heavy duty plastic products: - 101 lgf40 Isoplast, 101 lgf60 and 202 lgf40 (heat) ETPU glass filling amount of 40% to 60%, excellent chemical resistance and corrosion resistance at the same time.Hands in the nuts and bolts, scaffolding brackets and replace the metal applications such as release lever, they can improve the design flexibility and reduce machining operations.