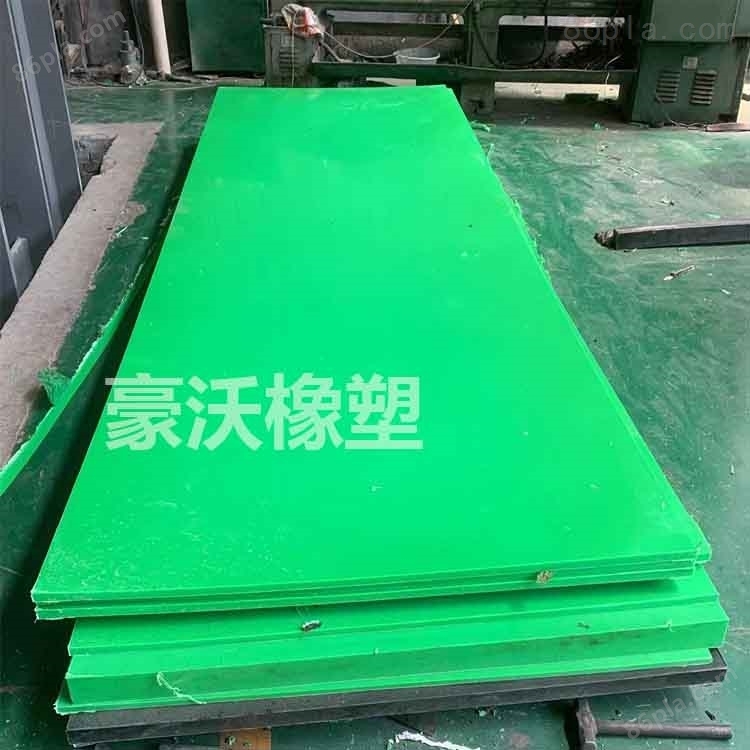

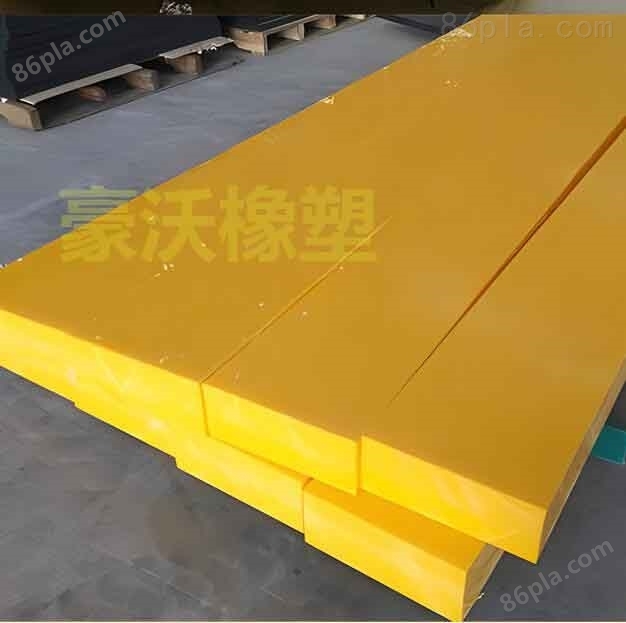

当前位置:山东豪沃橡塑有限公司>>超高分子量聚乙烯>> 定制高分子量耐磨抗老化聚乙烯板UHMWPE板

高分子量耐磨抗老化聚乙烯板UHMWPE板

Ultra high molecular weight wear-resistant and anti-aging polyethylene board UHMWPE board

高分子聚乙烯板产品特点:

(1) 耐磨特性,抗滑动摩擦能力强。超高分子量聚乙烯板耐磨性高于一般的钢管4-7倍,不锈钢的27.3倍。是酚醛树脂的17.9倍,尼龙六的6倍,聚乙烯的4倍,年磨损率平均值0.58㎜ ,提高了管道的使用寿命。

(2) 耐冲击性,在现有的工程塑料中超高分子量聚乙烯的冲击韧性值高,其抗冲击强度常温下是PE100的10倍以上。随着环境温度的降低,其抗冲击性能越强。

(3) 耐腐蚀性能,能耐绝大多数腐蚀性介质和有机溶剂的侵蚀,超高分子量聚乙烯可以在浓度小于80%的浓盐酸中应用,在浓度小于75%的硫酸、浓度小于20%的硝酸中性能相当稳定。

(4) 自润性,自身滑动性能优于用油润滑的钢或黄铜。在环境恶劣、粉尘、泥沙多的地方,超高分子量聚乙烯管自身干润滑性能更好。能运动自如,保护相关工件不磨损或拉伤。摩擦系数只有0.07~0.12,是普通PE的1/5,新钢管的1/6,橡胶的1/20。

(5) 无毒性,超高分子量聚乙烯材料是环保材料,无毒无味、防污抗蛀新型热塑性工程塑料。允许它用于与食品接触的场合。中国许多城市的主供排水道管都改用超高分子量聚乙烯管。

(6)耐低温性、抗老化,超高分子量聚乙烯管可长期在-269℃到80℃的温度下工作,由于分子链中不饱和分子团很少,分子量大,稳定性高,老化速度特别缓慢,使用寿命加长。

(7) 表面非附着性、不结垢,超高分子量聚乙烯管由于摩擦系数小和无极性,具有表面非附着性。

(8) 抗开裂性优,超高分子量聚乙烯管通过拉伸试验证明,它具有100~300%的延伸率,在承受巨大的外压和内压时或者是弯曲应力也能保持一定的变形而不断裂。

高分子量耐磨抗老化聚乙烯板UHMWPE板应用领域:

1.高分子量PE阻燃片材,用于煤矿井下作业及其他易自燃场所。

2.工程用高分子量PE板材代替钢材,具有高耐磨、耐化学性和耐腐蚀性。

3.Uhmw PE板材在低温处,能耐低温。

4.Uhmw PE板材可以在潮湿或深水中放置。

5.高分子量PE板材长时间放置阳光照射,不褪色。

6.高分子量聚乙烯板医疗场所获得辐射防护。

7.高分子量PE板材食品接触安全。

8.UHMW PE内衬溶液使用,摩擦系数低,不吸潮。

山东津鸿橡塑有限公司位于山东省德州市宁津县,处于京津、济南、石家庄等城市构成的三角地带,位置、环境雅、交通情况便利,公司主要产品:高分子量聚乙烯板(整板及切割板)棒,高密度挤出板(棒)、UHMWPE板、HDPE板、复合回字形枕木、冰球场围栏、支腿垫板、含硼聚乙烯板、工程塑料合金及各种加工件;

请输入账号

请输入密码

请输验证码

以上信息由企业自行提供,信息内容的真实性、准确性和合法性由相关企业负责,塑料机械网对此不承担任何保证责任。

温馨提示:为规避购买风险,建议您在购买产品前务必确认供应商资质及产品质量。