一、工作原理与适用范围 Working principle and scope of application

热泵干燥机是利用逆卡诺原理,吸收空气的热量并将其转移到房内,实现烘干房的温度提高,配合相应的设备实现物料的干燥。热泵烘干机工作同时又在回收干燥室排出的湿热空气中所含的显热和潜热,需要输入的能量只有热泵压缩机的耗功,而压缩机又有消耗少量功即可铺集搬运大量热量的优势,因此热泵烘干机组加热效率远大于其他方式的烘干设备,可以实现节能减排的效果。

热泵烘干机组主要适用于农副产品脱水烘干,如银耳、瓜子、花生、果蔬、肉制品、肠衣、烟叶、香菇、枸杞、粮食、腐竹、海产品、中药材等。化工方面也有大量应用,如纸品、木材、污泥、石膏、粘土、煤泥等的烘干。在工业热水方面,还可满足电镀厂电镀液的恒温、屠宰场高温热水的加热和保温,星级酒店高温热水的供应和工业企业高温热水的需求以及床上用品的烘干等。

Heat pump drier utilizes the reverse Carnot's principle to absorb the heat of air and transfer it to the room to realize the temperature increase of the drying room and cooperate with corresponding equipment to realize drying of materials. The heat pump drier recycles the sensible heat and potential heat contained in the wet and hot air exhausted by the drying room while operating, the energy that shall be input is the power consumption of heat pump compressor only, and the compressor has the advantage that a lot of heat can be gathered and transferred by consuming a small amount of power, therefore, heating efficiency of heat pump drying unit is much larger than that of other drying equipment and it can realize the effects of energy conservation and emission reduction.

Heat pump drying unit is mainly suitable for dehydration and drying of agricultural and sideline products, such as tremella, melon seeds, peanuts, fruits and vegetables, meat products, casing, tobacco, mushrooms, medlar, grain, dried bean milk cream in tight rolls, marine products, traditional Chinese medicinal materials. It is also widely used in chemical aspect, for example, drying of paper products, wood, sludge, gypsum, clay, coal slime, etc. In the industrial hot water aspect, it can also meet meet the requirements of constant temperature of electroplate liquid of electroplate factory, heating and heat preservation of high-temperaturehot-water of slaughter house, supply of star hotel high temperature hot water and high-temperature hot water of industrial enterprises, and drying of bedding article.

二、特点Characteristics

1. 高效节能。热泵干燥装置SMER(消耗单位能量所除去湿物料中的水分量)通常为1.0~4.0kg/kWh,而传统对流干燥器的SMER值约为0.2~0.6kg/Kwh。

2. 可实现低温空气封闭循环干燥,物料干燥质量好。通过控制装置的工况,使干燥室的热干空气的温度在20~80℃之间,可满足大多数热敏物料的高质量干燥要求;干燥介质的封闭循环,可避免与外界气体交换所可能对物料带来的杂质污染,这对食品、药品或生物制品尤其重要。此外,当物料对空气中的氧气敏感(易氧化或燃烧爆炸)时,还可采用惰性介质代替空气作为干燥介质,实现无氧干燥。

3. 环境友好。热泵干燥装置中干燥介质在其中封闭循环,没有物料粉尘、挥发性物质及异味随干燥废气向环境排放而带来的污染;干燥室排气中的余热直接被热泵回收来加热冷干空气,没有机组对环境的热污染。

4. 与其它低温(进干燥室空气温度<>

Efficient and energy-saving. Heat pump drying unit’s SMER (Specific Moisture Extraction Rate ) is generally 1.0~4.0kg/kWh and SMER value of traditional convection drier is about 0.2~0.6kg/Kwh.

It can realize low-temperature air closed cycle drying and has good material drying quality. Through controlling the working condition of unit, the temperature of hot and dry air in the drying room is at 20~80℃. It can meet the high quality drying requirements of most of the heat sensitive materials; closed cycle of drying medium can prevent the impurity contamination possibly brought by exchange with external gas to the materials, which is very important for food, drugs or biological products. In addition, when the materials are sensitive to the oxygen in the air (easy for oxidation or burning e xplosion, the inert medium can be used as a drying medium instead of air to realize anaerobic drying.

It is environment-friendly. The drying medium conducts a closed cycle in the hot pump drying unit without contamination of material dust, volatile substance and peculiar smell brought by discharge of drying waste gas to the environment; the afterheat in the exhaust gas of drying room is directly recycled by heat pump to heat the cool and dry air without thermal pollution of unit to environment.

Compared with other low-temperature (inlet air temperature of drying room<40℃) drying="" units="" (such="" as="" microwave="" drying,="" vacuum="" drying="" and="" freeze="" drying),="" heat="" pump="" drying="" unit="" has="" obvious="" economical="" efficiency="" due="" to="" small="" initial="" investment="" of="" equipment="" and="" low="" operation="" cost.="" the="" heat="" pump="" drying="" unit="" is="" mainly="" composed="" of="" heat="" pump="" and="" drying="" room,="" of="" which="" the="" drying="" room="" has="" the="" same="" requirements="" with="" convection="" drying="" room,="" without="" special="" air="" tightness="" and="" pressure-bearing="">

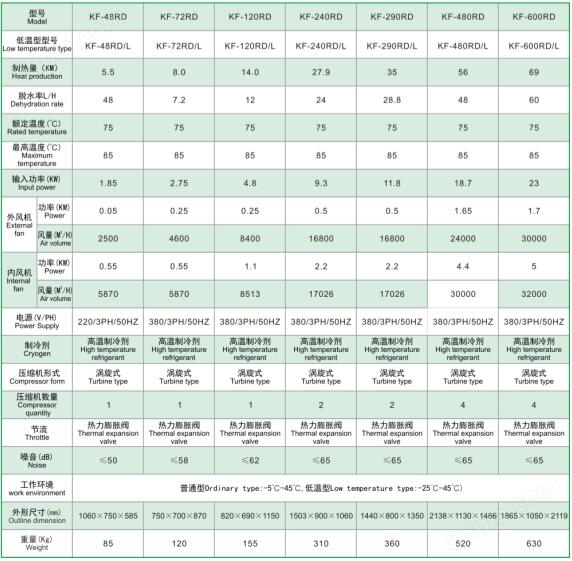

三、技术参数(下表中数值仅供选型时参考)

Technical parameters (the values in the table below are for reference in type selection only)

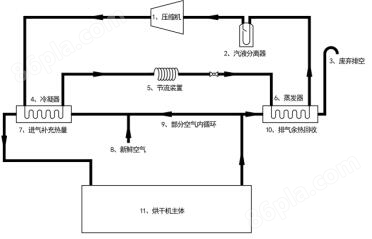

四、工艺流程图Process flow diagram

热泵烘干机Heat Pump Drier

| 参考价 | 面议 |

具体成交价以合同协议为准

- 公司名称四川川大干燥科技工程有限责任公司

- 品 牌

- 型 号

- 所 在 地成都市

- 厂商性质其他

- 更新时间2023/7/27 9:29:35

- 访问次数310

四川川大干燥科技工程有限责任公司(简称:川大干燥)是于2001年成立的一家集技术研发、技术转让、装备制造加工的企业。川大干燥行政管理与设计研发部门设在四川大学科技创新中心大楼内;生产和试验科研基地位于成都羊安镇工业园区内,并独自建设有加工制造中心与产品测试展演中心。公司从建立之初即着力科技研发,重心即着力医药、食品等方面的工艺技术研究与*装备的研制上。公司具有门类学科齐全的专业研发队伍,所研发的产品品质优良、性能可靠、外形美观;经过近三十年的产业技术研究、产品技术研制、产出技术研验,已具有独立自主知识产权的工艺及配方生产技术三项;固体制剂系列装备已研制有十二类近两百种不同规格。而今川大干燥严格按照新版GMP精心研制的制药与食品装备无论是在技术性能上,还是在性价比上都处于同行前列。现“川大干燥”的产品与服务无论在中国还是在世界各国的制药、食品、保健品、动物药业等行业以及其它行业均享有盛誉,已经形成特色与影响力的品牌。川大干燥除了在制药与食品等行业提供良好技术服务与优良产品以外,川大干燥还拥有包括工业粉尘净化回收技术与系统工程装备研制技术、大气净化环保工程装备与家用PM2.5净化器等系列产品技术。川大干燥向提供的优良装备产品有:各种烘干设备、各种造粒设备、各种混料设备、各种粉碎设备、各种筛分设备、各种灭菌设备、各种浓缩提取设备、各种环保设备等等。川大干燥向提供*的具有自主知识产权的工艺及装备总包的项目有:l 鸡精调味料工艺技术、工艺配方生产技术,鸡精调味料全套生产线。l 高品位高纯度三偏磷酸钠工艺生产技术以及生产线(川大干燥起草的三偏磷酸钠国家标准已于2015年3月正式公布实施)。l 鲜榨提取制取方便型老姜汤冲剂工艺技术以及全套生产线等等。

真空干燥设备

一、工作原理与适用范围Workingprincipleandscopeofapplication热泵干燥机是利用逆卡诺原理,吸收空气的热量并将其转移到房内,实现烘干房的温度提高,配合相应的设备实现物料的干燥

热泵烘干机Heat Pump Drier 产品信息

在找 热泵烘干机Heat Pump Drier 产品的人还在看