用途:

适用于输送液压流体和水性流体。

特性:

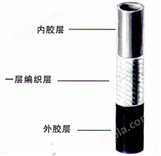

用耐油和耐天候良好的特种橡胶制造,采用镀铜钢丝编织增强,外观为黑色布纹。软管执行SAE J517 100RIAT/R2AT标准。DIN EN853 1SN. 2SN标准.工作温度- -40°c ~+135'C(- 40°F~+275'F).

| 规格 SIZE | 软管内径 I.D | 增强层外径 W.D | 外胶层厚度 | 工作压力 Max.W.P | 试验压力 P.P | 爆破压力 Min.B.P | 弯曲半径 Min.B.P | 参考重量 W.T. | |||

| Inch | Min | Max | Min | Max | Min | Max | MPa | MPa | MPa | mm | kg/ m |

| 3/16-1 | 4.6 | 5.4 | 9 | 10 | 0.8 | 1.5 | 21 | 42 | 84 | 90 | 0.2 |

| 1/4-1 | 6.2 | 6.9 | 10.6 | 11.6 | 0.8 | 1.5 | 19.3 | 38.5 | 77 | 100 | 0.23 |

| 5/16-1 | 7.7 | 8.5 | 12.1 | 13.3 | 0.8 | 1.5 | 17.5 | 35 | 70 | 115 | 0.28 |

| 3/8-1 | 9.3 | 10.1 | 14.5 | 15.7 | 0.8 | 1.5 | 15.8 | 31.5 | 63 | 130 | 0.33 |

| 1/2-1 | 12.2 | 13.5 | 17.5 | 19.1 | 0.8 | 1.5 | 14 | 28 | 56 | 180 | 0.4 |

| 5/8-1 | 15.5 | 16.7 | 20.6 | 22.2 | 0.8 | 1.5 | 10.5 | 21.o | 42 | 200 | 0.48 |

| 3/4-1 | 18.6 | 19.1 | 24.6 | 26.2 | 0.8 | 1.5 | 8.7 | 17.5 | 35 | 240 | 0.62 |

| 1-1 | 25 | 26.4 | 3.25 | 34.1 | 0.8 | 1.5 | 7 | 14 | 28 | 300 | 0.91 |

| 1/4-1 | 31.4 | 33 | 39.3 | 41.7 | 1 | 2 | 4.3 | 8.7 | 17.5 | 420 | 1.18 |

| 1/2-1 | 37.7 | 39.3 | 45.6 | 48 | 1.3 | 2.5 | 3.5 | 7 | 14 | 500 | 1.42 |

| 2-1 | 50.4 | 52 | 58.7 | 61.7 | 1.3 | 2.5 | 2.6 | 5.2 | 10.5 | 630 | 1.5 |

| 3/16-2 | 4.6 | 5.4 | 10.6 | 11.6 | 0.8 | 1.5 | 35 | 70 | 140 | 90 | 0.32 |

| 1/4-2 | 6.2 | 6.9 | 12.1 | 13.3 | 0.8 | 1.5 | 35 | 70 | 140 | 100 | 0.35 |

| 5/16-2 | 7.7 | 8.5 | 13.7 | 14.9 | 0.8 | 1.5 | 29.7 | 59.5 | 119 | 115 | 0.41 |

| 3/8-2 | 9.3 | 10.1 | 16.1 | 17.3 | 0.8 | 1.5 | 28 | 56 | 112 | 130 | 0.5 |

| 1/2-2 | 12.3 | 13.5 | 19 | 20.6 | 0.8 | 1.5 | 24.5 | 49 | 98 | 180 | 0.62 |

| 5/8-2 | 15.5 | 16.7 | 22.2 | 23.8 | 0.8 | 1.5 | 19.2 | 38.5 | 77 | 200 | 0.72 |

| 3/4-2 | 18.6 | 19.8 | 26.2 | 27.8 | 0.8 | 1.5 | 15.7 | 31.5 | 63 | 240 | 0.92 |

| 1-2 | 25 | 26.4 | 34.1 | 35.7 | 0.8 | 1.5 | 14 | 28 | 56 | 200 | 1.3 |

| 1/4-2 | 31.4 | 33 | 43.3 | 45.6 | 1 | 2 | 11.3 | 22.7 | 45 | 420 | 1.8 |

| 1/2-2 | 37.7 | 39.3 | 49.6 | 52 | 1.3 | 2.5 | 8.7 | 17.5 | 35 | 500 | 2.2 |

| 2-2 | 50.4 | 52 | 62.3 | 64.7 | 1.3 | 2.5 | 7.8 | 15.7 | 31.5 | 630 | 3 |